OEM and ODM plastics design and manufacturing in China

Our experienced design team collaborates closely with our production engineers to bring new premium plastic products to life.

We’re trusted worldwide for our design and engineering skills, innovation and on-time delivery.

Your one stop solution for plastics products

Our full range of services and in-house production facilities ensures product quality and integrity every step of the way.

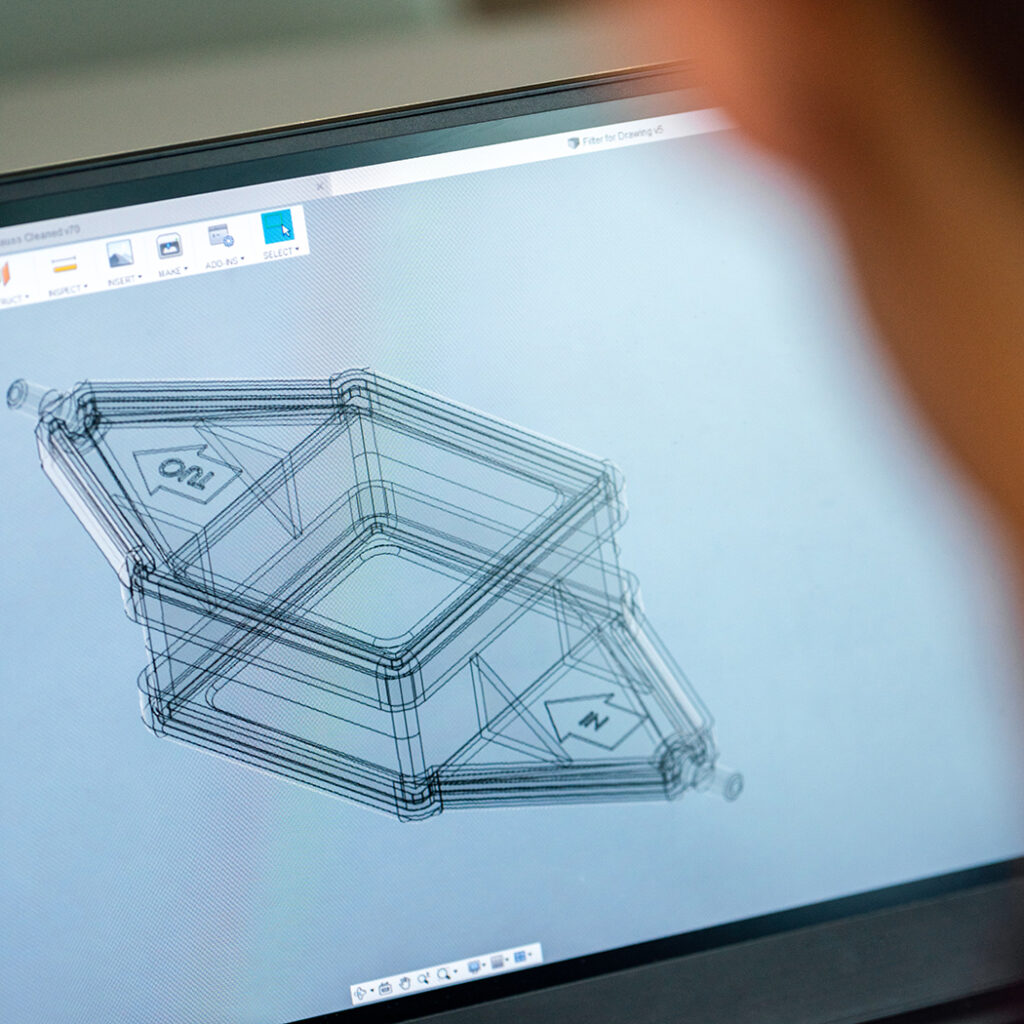

Product design and development

Complete product design service from concept to production. We provide 3D drawings and renderings, tooling, sourcing for all materials and non-plastic components. All to match your needs and budget.

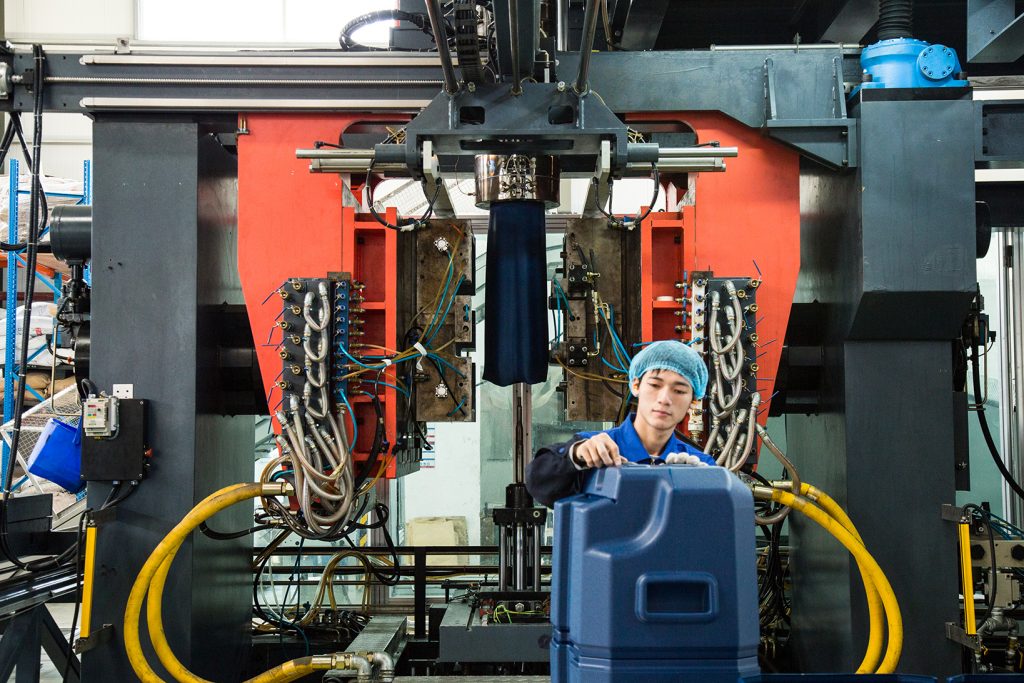

Injection and blow moulding

Our 20+ injection moulding machines range from 120 to 2500 tonnes. Our Cooler Division blow moulding machines range from 500ml to 150 litres.

Tooling, prototypes and sampling

We work closely with a broad network of toolmakers and monitor the entire mould creation process. From 3D models to prototypes to production-grade samples, each stage undergoes rigorous testing for client approval.

PU foaming

Typically used for insulation of hard coolers, our foaming carousels can handle up to 48 jigs per cycle. Using polyurethane foam, we can produce coolers that retain ice for up to eight days. All jigs are custom-designed by our team.

Product assembly

Skilled, highly trained teams manage pre-assembly to the packaging the finished product. Quality control supervisors ensure all products pass meticulous inspection protocols.

Packaging and POS

We customise and brand products with screenprinting, hot stamping, heat transfer and/or moulded inserts. We can provide eye-catching point-of-sale and packaging solutions. Our design team manages the complete printing and production process - so products can be transported, unpacked and put straight onto store shelves.

Sourcing

Our dedicated team sources non-plastic components from our wide network of quality-led, reliable suppliers. From design to sampling and quality control, our team manages the entire process for our customers.

Quality control

Quality control supervisors monitor the entire process through all stages of production. We maintain stringent control procedures to ensure total product integrity. As responsible suppliers, we hold ourselves accountable and move quickly to remedy any quality issues.

World class manufacturing standards

Our facilities are inspected and audited each year by leading international companies.

Our 350 full-time team work in strict compliance with government labour laws. Each is provided with regulatory benefits and participates in our bonus scheme incentives.

We highly value every team member and have built a culture of collaboration, mutual support and care across our business.

Dedicated insulated cooler factory

Built in 2013, our Cooler Division manufactures both home and commercial coolers for our international and local customers.

Our blow moulding machines produce 2 to 150 litre hard coolers. All inners and lids are made with food-grade raw materials and comply with US FDA food safety standards and requirements.

We own more than 65 precision moulds and over 120 custom-built jigs used in the PU foaming process.

| Area | 6,311 sqm |

|---|---|

| Workshop | 1,547 sqm |

| Assembly | 1,944 sqm |

| Warehouse | 2,382 sqm |

| Design studio and administration | 438 sqm |

| Machinery | |

|---|---|

| Injection moulding machines | 6 |

| Blow moulding machines | 3 |

| Hot & cold gel line packaging machines | 3 |

| PU foaming | |

|---|---|

| PU foaming machines | 2 |

| Carousels | 2 |

| Product printing | |

|---|---|

| Heat transfer machine | 2 |

| Screen printing machine | 1 |

| Hot stamp machine | 1 |

| Certifications | |

|---|---|

| ISO9001:2000 | |

| GB/T 19001-2000 |

Standard plastic products factory

Constructed in 2010, our Standard Products Division primarily develops and manufactures household and material handling products for the Chinese domestic industrial market.

Products include plastic pallets, crates, totes, boxes and a limited number of traditional plastic homeware products. The division also produces small parts for the Cooler Division.

We have developed, maintain and own more than 200 moulds used to manufacture our Rodman and Pearl River product ranges and supply OEM brands.

| Area | 18,047 sqm |

|---|---|

| Workshop | 3,672 sqm |

| Assembly | 1,170 sqm |

| Warehouse | 5,592 sqm |

| Design studio and administration | 1,350 sqm |

| Material handling area | 2,500 sqm |

| Loading area | 3,763 sqm |

| Machinery | |

|---|---|

| Injection moulding machines | 17 |

| Extrusion machine | 1 |

| Product printing | |

|---|---|

| Hot stamp machine | 1 |

| Certifications | |

|---|---|

| ISO9001:2000 | |

| GB/T 19001-2000 |